Industrial Process Automation Compact Station Trainer – Virtual

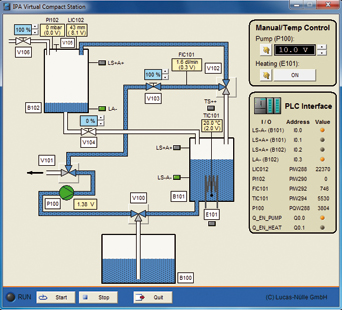

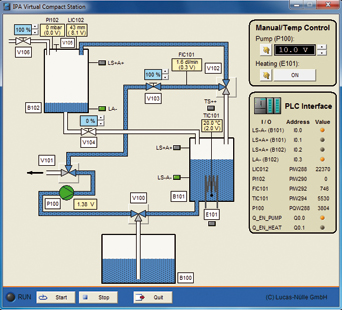

IPA Virtual is a PC-based, graphic simulation system which provides the virtual learning environment for the Industrial Process Automation Compact Station Trainer.

This system is programmed like the real model using STEP 7 and is controlled via the PLCSIM software. Furthermore, the model can be operated with the integrated controllers without any additional software.

The system covers all relevant areas from commissioning the compact workstation all the way to control loop optimisation. The program developed to operate the simulation system can be uploaded for work directly with the real compact station.

The following process control technology models are integrated into the simulation system:

- Automatic pressure control

- Automatic flow-rate control

- Automatic filling level control

- Automatic temperature control

- Automatic cascade control of filling level

- Graphic animation of filling levels and flow rates in real time

- All of the indicators, like pressure and flow-rate are displayed as values

- Integrated connection to PLCSIM permits programming with STEP7

- Integrated continuous (PID) and discontinuous (two-position) controller

- Graphic evaluation of measured values for calculating optimum controller parameters

- Characteristics plotter records all measured values over time

- Integrated operator panel including all of the pushbuttons, switches and signalling lights required to operate the system

- For troubleshooting purposes various malfunctions, for example, defective sensors and actuators can be simulated

Product: Industrial Process Automation Compact Station Trainer – Virtual

Product Code: IPA Virtual