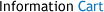

Unceasing advances in the development of hybrid and all-electric vehicle technology continue to pose new challenges for the automotive sector. The high-voltage (HV) battery has long been considered to be a “black box”. But now, more and more manufacturers are also venturing into repairing HV batteries.

This involves lots of challenges and requires a special understanding of “overall systems” in order for proper work to be possible. This training system focuses on the digitally networked CAN-bus battery management system in a traction battery and on the corresponding components.

Particularly important here were the activities involved in the measuring and operational testing of HV components carrying a voltage. Practical and live exercises involving the measurement and diagnosis of battery cells are carried out. The HV battery is designed such that it can be taken apart to replace individual cells and sensors. This is how the trainee develops skills and practices diagnosing and maintaining the HV battery.

- Understand customer complaints, carry out operational testing and determine diagnostics approach

- Read out fault memory

- Check effectiveness of electrical safety measures on the high-voltage system

- Replace high-voltage components

- Become familiar with location of components in the motor vehicle

- Determine faults and their causes with the aid of circuit diagrams and function plans

- Draft an inspection protocol and document results

- Understand measures taken to avoid hazards caused by voltage isolation faults

- Learn about data communication between control units

- Recognise repair needs and carry out repair options

- Determine diagnostics and repair options based on a customer’s job order

- Determine system operating states with the aid of the diagnostics systems, compare these to information in databases and evaluate results

- Measuring and testing systems

- Determine the desired data

- Select measurement procedure and measuring instruments

- Document the measurement results

- Determine the measurement results, compare these to the desired data and evaluate

- Measure, check and evaluate signals at components and systems

- Measure, test and evaluate electrical connections

- Test high-voltage systems with diagnostics equipment, in particular perform measurements on isolation, equipotential bonding and voltage drops

- Analyse and evaluate messages in data bus systems

- Learn how battery cells are designed and function in the HV battery

- Learn how temperature sensors are designed and function in the HV battery

- Design and function of HV charging systems

- Evaluate work safety

- Advantages and disadvantages of individual HV charging systems

- Options to practically measure power consumption for different driving profiles

- Measuring voltage characteristics in HV batteries for different charging and discharging cycles

- How sensors and actuators interact

- IPO principle

- Open-loop control processes in the motor vehicle

- Closed-loop control processes in the motor vehicle

- Differences between open- and closed-loop processes

Product: Light Vehicles High Voltage Battery Diagnosis and Repair Trainer

Product Code: CO3221-6S