In the past, training painters typically involved costly, time consuming, and labour intensive in-booth training. Training was expensive.

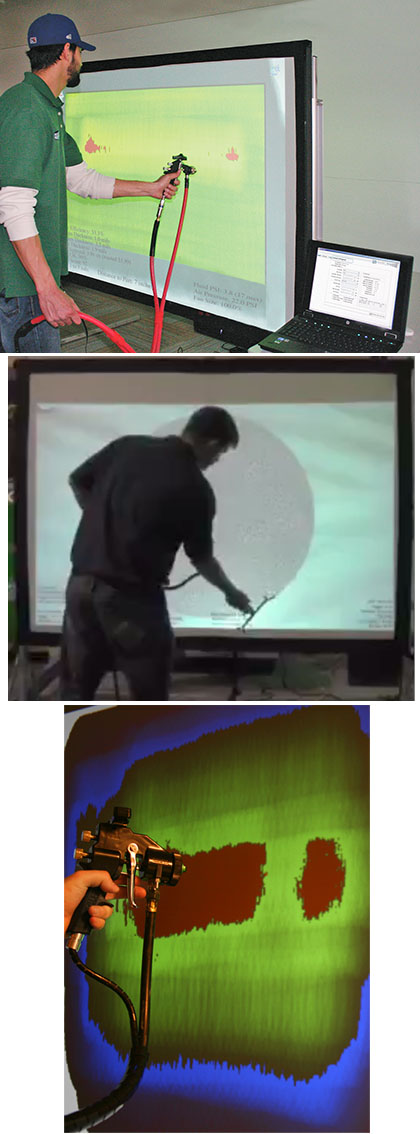

VirtualPaint provides realistic, hands-on painter training which can be conducted in a classroom or workshop. VirtualPaint allows the user to view and interact with real spray application equipment, while simulating the actual application process onto a virtual surface (eg. a projector screen). By using this technology, no hazardous emissions or wastes are produced through the training process, creating a much safer environment for students and trainers alike.

Click here to learn more about the VirtualPaint

Instructors can provide effective training demonstrations, address spray gun setup and proper application in front of a class of any size. Instructors can also watch students practice and identify the abilities and the levels of understanding that each student demonstrates by using a combination of observation and the inbuilt VirtualPaint performance measures and reports. This allows for accurate and meaningful feedback and assessment for the students.

VirtualPaint is currently being used in Australia, New Zealand and around the world to train painters in automotive, furnishing, design and other industries and at all levels – from those with no experience to those at advanced levels – and in a variety of settings including:

- TAFE & Technical Colleges

- Universities

- High Schools & Trade Training Centres

- Industrial & Military Facilities

- Coatings Manufacture Facilities

- Collision Repair & Trade Facilities

The new VirtualPaint8 software offers users enhanced simulation accuracy (based on extensive research by University of Iowa), enhanced coating characteristics and spray techniques and improved film visualisation. Enhanced effects such as rotating air cap, changing fluid tip and real time flow rates have been added together with real-world visual effects including coverage, gloss, orange peel, sagging/runs and tiger striping.

Using the VirtualPaint as part of your spray paint training has many reported benefits. Feedback from existing users includes:

- Increased Training Value including: learning to optimise equipment set-up and spray techniques, improved film thickness consistency, improved transfer efficiencies and reduced re-work times and costs.

- Elimination of Hazardous Emissions & Waste which provides both safety and environmental benefits.

- Sustainable Training Costs Savings including: major reductions in training material expenses, reduced preparation & clean up times and reduced insurance costs in light of reduced risks to trainers and trainees.

- A Better & Easier Way to Train including: immediate results and precise feedback on aspects such as the thickness of the coating (if selected), repetitive practice to improve motor skills, refining & improving techniques of experienced painters and a wide range of training scenarios to suit different environments.

- Measurable & Repeatable Scenarios provide the ability to track student performance in an unbiased manner during the course of their training and to accurately compare student or employee performance.

- Interactive Classroom Environment including: improved student engagement when learning using this technology,ability to conduct training and demonstrations safely for large groups and an almost unlimited number of coatings and parts.

- Unlimited Practice at the Touch of a Button at no extra cost and in a safe environment reduces the learning curve and can significantly improve overall efficiencies.

- Employee Performance Assessment including: non-biased evaluation and testing of the skills and techniques of potential employees.

- Ability to Customise aspects such as users, lesson, coatings and parts means that the system is highly flexible and can quickly be adapted to different training scenarios within the same institution.

The new VP8 software is also capable of supporting a range of spray gun types and offers several different training modes to cater for different uses. As part of a SPECIAL PROMOTION for orders placed before 31 December 2014, we are pleased to advise that in addition to the Skill Development Mode and Instructor Design Mode which forms part of the standard system, we will be giving customers the Skill Evaluation Mode at no additional charge. This represents a significant saving to your Institute and enhances your ability to test a painter’s skills based on a lesson plan and set of options and characteristics selected.

To find about more about the VirtualPaint hardware, the different modes, spray guns and other VirtualPaint features, please feel free to contact us on +613 9557 7993.